3D PRINTING INSTRUCTIONS

The following are instructions for 3D Printing Cannagar Tools on your own FDM 3D printers.

These are the identical settings used in Cannagar Tools manufacturing.

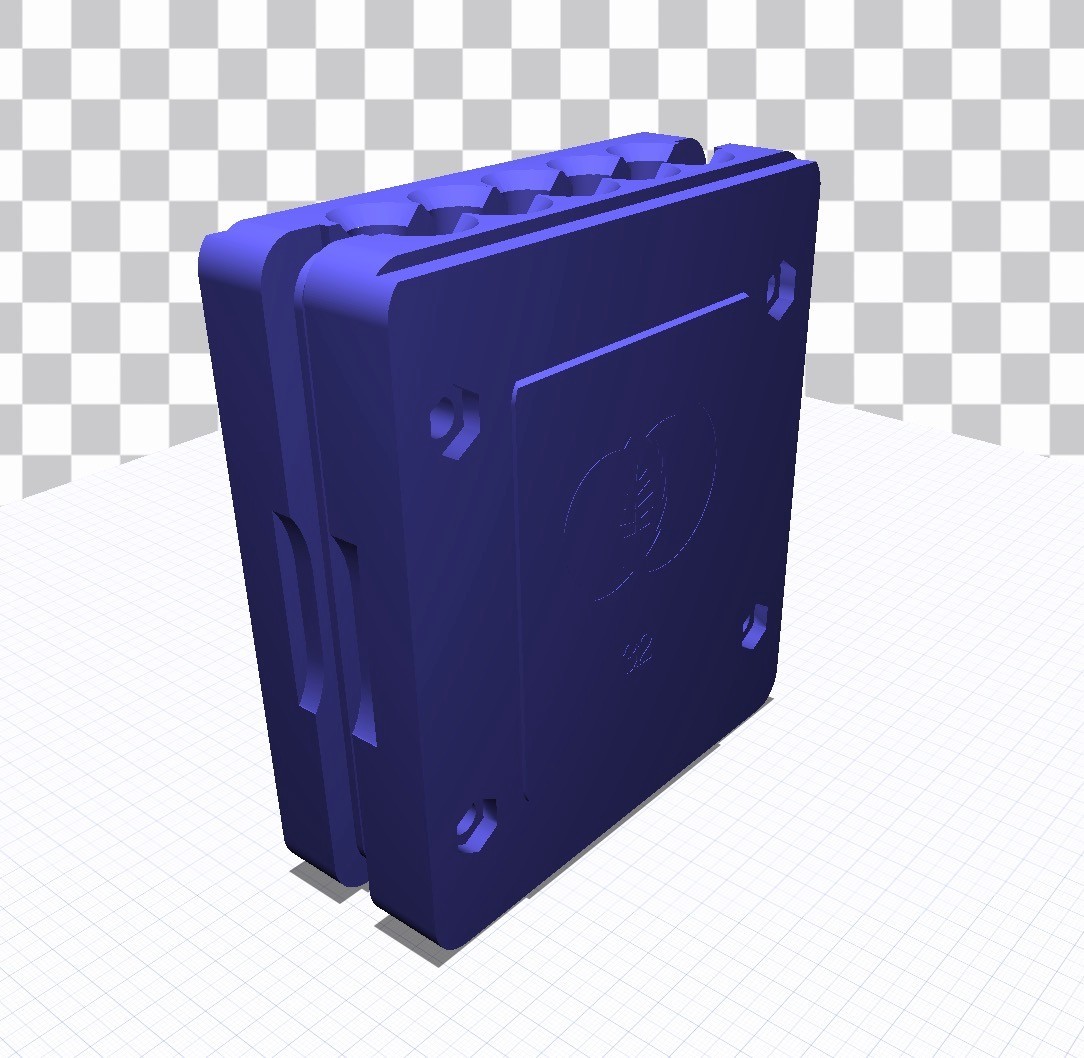

Stackable Molds and BudDrivers

Minimum Printer Requirements :

6" x "6 (X / Y) Build Plate

8" Build (Z)

Slicer Settings for PLA

*Print Speed : 60mm/s

Layer Height : 0.3mm

Perimeter / Shell : 4

No Supports Needed

*Speeds will be dependent on your machine and tolerances.

**4mm is the minimum recommended for strength of the part

Stackable molds are designed to be printed vertically in the orientation provided in the STL files.

Any modification to orientation will produce negative results.

They come out clean and mostly ready to use, right off the printer.

Photos seen on 3D printable product listings are example photos meant to show the mold shape.

Molds should not rotated and printed flat against the print bed.

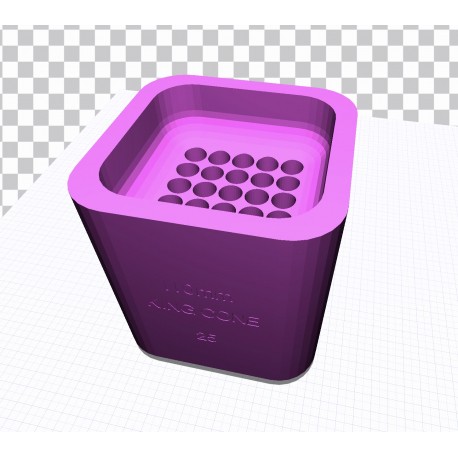

Pre Roll Loaders

Minimum Printer Requirements :

9" x 7" (X/Y) Build Plate for 25, 50 Slot Loaders

12" x 12" (X / Y) Build Plate for 100 Slot Loaders

8" Build (Z)

Slicer Settings for PLA / Flex PLA

Slicer Settings for PLA / Flex PLA*Print Speed : 60mm/s

**Nozzle : 4mm

Layer Height : 0.3mm

Perimeter / Shell : 4

Supports Needed

Slicer Settings for TPU

*Print Speed : 30mm/s

**Nozzle : 5mm

Layer Height : 0.3mm

Perimeter / Shell : 3

Supports Needed

*Speeds will be dependent on your machine and tolerances.

**4mm is the minimum recommended for strength of the part

PLA will produce a fairly breakable Pre Roll Loader.

This is due to the weight of the unit.

If dropped, it is almost guaranteed to take some damage if made from PLA.

It is recommended to use TPU or Flex PLA to create a more or less indestructible Pre Roll Loader.

Cannagar Tools uses FlexPLA by Paramount 3D.

As seen on the Affiliated Products page.